Customised racking solution

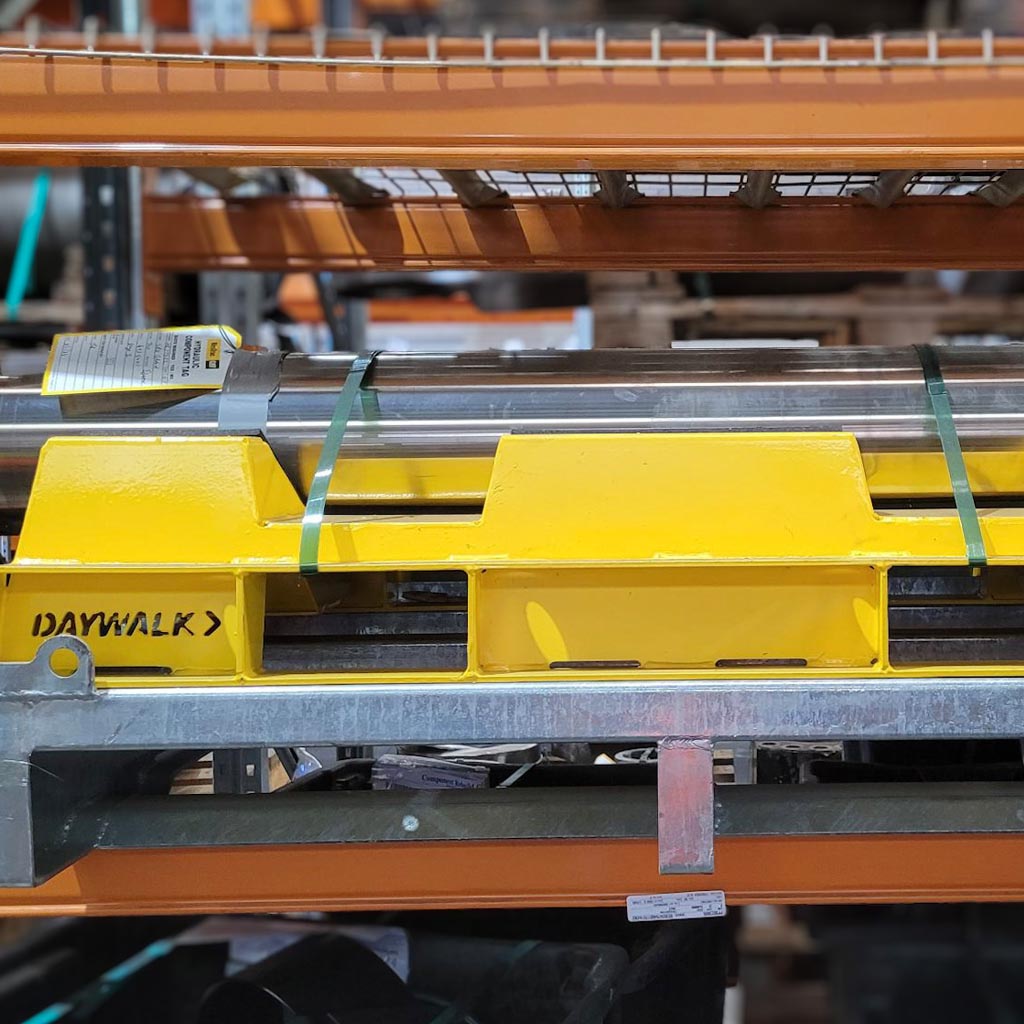

Daywalk provided WesTrac with a specialised rod and barrel storage system designed to address their unique challenges.

A base pallet seamlessly slotted into the existing racking system to significantly improve racking compatibility.

Two cassette ‘children’ locked into a ‘mother’ pallet to securely hold the rods and barrels.

Pallet-racking compatible and keeps rods and barrels together rather than separate, helping operations to run smoothly.

The locking mechanism of the cassettes into the mother pallet ensured that the rods and barrels were held securely, reducing the risk of accidents.

Magnetic separator drums are transported safely, with ease.

“Awesome work from your DAYWALK team gentlemen. Improving safety across the board from manual handling, working at heights and also reducing risk to freight moving in transport.” – Warehouse & Logistics Superintendent, Fortescue

“Hi gents, Just walking around the yard here at Kenwick and saw this new beauty with a separator from Camco going to Fortescue’s Iron Bridge site – you’ve made me very happy! Thanks for adding the twist lock pockets to the design!” – Head of HSEQC, Ktrans