The metal cage is slowly taking over the transporting and shipping of goods across many countries in the world today. In fact, metal cages are gradually replacing wooden pallets, barrels, kegs, boxes, and crates simply because all these mentioned can be carried in one single metal cage, and in a much safer way.

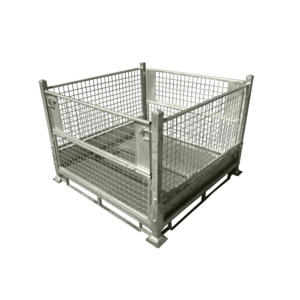

Unlike a wooden pallet that is simply flat with no sidewalls, metal cages have a flat galvanised metal flooring with steel mesh sides for added protection. In short, the whole metal cage is manufactured from sturdy galvanised steel, assuring strength and durability, and prevents rust and corrosion. Some metal cages come with lockable lids for security or half-fold down gates for easy access to goods.

Made for all goods

Unlike wooden pallets that can be contaminated by the goods it carries, metal cages can transport anything from drums, containers of liquids or chemicals, food, materials, clothes, technology, and even heavy equipment. It can safely carry vital spare parts and materials, reduce the amount of space used to carry these goods, and prevents damage when in transit. The products carried can either be lifted as a single cage or removed individually, depending on the need. Metal cages cannot be contaminated by the goods they carry because the cages are easily cleaned off using standard cleaning materials. Chemicals and liquids will not absorb through the metal.

Transportable and stackable

Steel cages are compatible with all forklifts, pallet trolleys, and automatic lifters. They are made to be lifted from any side since all sides have gaps for lift spikes. The anti-tipping bars are there in case the metal cage becomes unbalanced because the goods inside shifted, so the cage will not tip over, giving enough time for the cage to be set down and the goods inside re-arranged. This significantly reduces the risk of injury to workers. Steel cages are also stackable up to three high. The cage is easily dismantled for secure storage when not in use, taking up very little space even if several are stacked up or set side-by-side. The cage is easily assembled and folded out for immediate use.

Fire issues

Naturally, because metal cages are made of galvanised steel, they are not as large fire hazards, unlike wooden pallets. This is important if the cages happen to be transporting flammable liquids or chemicals in sensitive drums or containers. Should a fire break out, the metal cage may actually reduce the high temperature since galvanised steel is impervious to heat.

Design specifications

When deciding on a specific metal cage, one must take into account the effectiveness of the design specifications since cages come in different shapes and sizes. Some metal cages are even designed for specific uses. You also need to consider the weight and size of the goods being carried. The bigger and heavier the goods, the more structure and strength is required.

For example, take the Daywalk range of metal cages that come in sizes ranging from 300mmH, 500mmH, 800mmH, 900mmH, and 1420mmH. There are choices of fixed mesh sides, single or double lift-fold down gates or hinged gates, and lockable lids. There is even a metal cage double width that is the size of two cages combined for heavier or uneven loads.

For enquiries on metal cages or to request a quote, visit the Daywalk website at https://daywalk.com/.