DAYWALK’s Volatile Corrosion Inhibitor (VCI) range is designed to protect valuable assets from rust and corrosion during storage and transport.

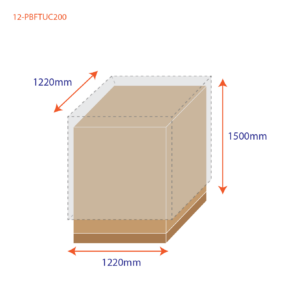

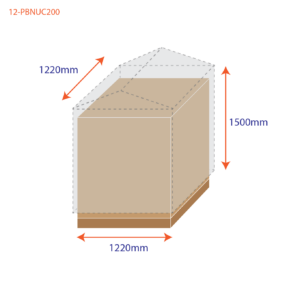

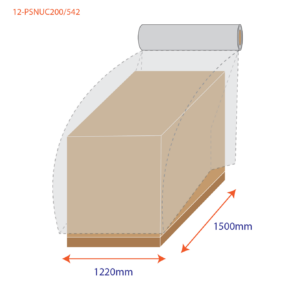

VCI packing films are flexible sheets used to wrap or line pallets, providing versatile coverage. VCI bags are pre-formed to fully enclose goods for convenient, airtight protection. VCI covers are larger solutions ideal for pallets, machinery or bulk equipment. Although they differ in applications, they all work in the same manner, releasing protective vapours that form an invisible barrier to water and contaminants. The process makes metals rust-free without the mess of oils or greases.

DAYWALK offers convenient sizes, shapes and forms with related products like VCI desiccants for additional moisture protection. Desiccant packages are generally used in combination with VCI film, bags and covers to attract remaining moisture, providing an additional layer of protection for sensitive metals during storage and transport.

Showing 1–16 of 18 results

With DAYWALK’s VCI protection, pallets, machinery and equipment remain safeguarded from corrosion even in humid or outdoor conditions, without the need for constant checking, oiling or re-wrapping. Our VCI solutions range allows you to choose the right form for your site requirements, whether it’s lining a pallet, fully enclosing a part or covering heavy equipment.

What sets DAYWALK apart is our focus on compliance, quality and integration with load restraint systems. Unlike other brands, our products are engineered for industrial use and work seamlessly with products such as our heavy-duty metal pallet, providing you with long-term asset protection and peace of mind.

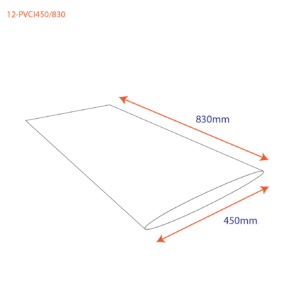

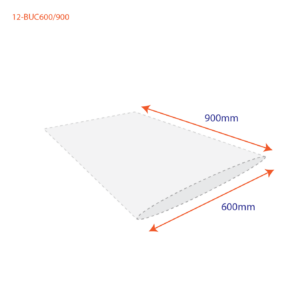

VCI bags protect metal parts, machines or equipment from rust and corrosion during storage and transit. Made from durable plastic and infused with VCI chemicals, the bags release invisible vapours that form protective layers on metal surfaces. This eliminates the need for oils or greases, keeping goods clean, dry and ready for use straight out of the bag.

Some VCI bags can be reused if they remain intact, clean and uncontaminated, but the corrosion-preventing vapours slowly get absorbed over time, restricting reusability. Prolonged use of a bag can also downgrade the level of protection. It’s best to inspect the bag’s condition and replace it if protection might be compromised.

For optimal corrosion protection, all VCI bags must always be sealed or closed. This can be done by folding, heat sealing or taping, depending on the use. Sealing keeps the protective vapours at a close concentration inside, providing a corrosion-inhibiting environment around the metal. DAYWALK provides heatshrink guns and tools, making it simple to seal VCI film around machinery or pallets securely.

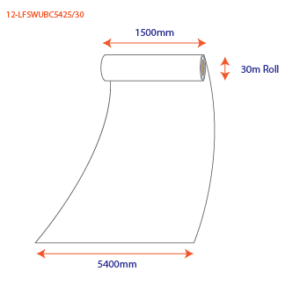

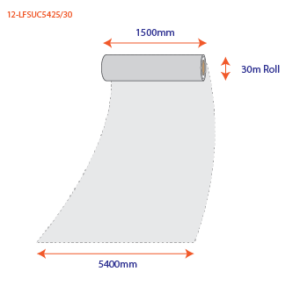

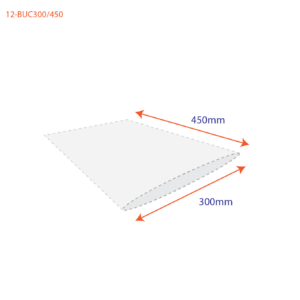

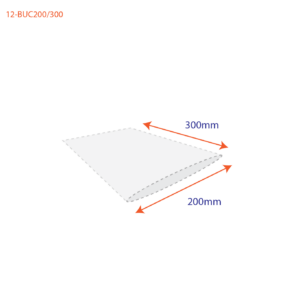

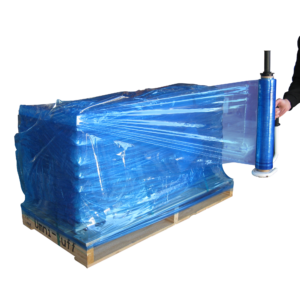

VCI film is a pliable plastic packaging material that guards against corrosion and rust in metal products when in storage or transport. The VCI chemical contained in the film releases protective vapours that create an imperceptible layer on metal surfaces.

VCI film is highly versatile and used in many sectors. It can cover pallets, line crates, blanket equipment and protect steel components during storage and shipping. Safe for all common metals, including steel, iron and aluminium, VCI film prevents rust without oils or greases. It works effectively alongside robust storage options, such as steel stillages for long-term protection.