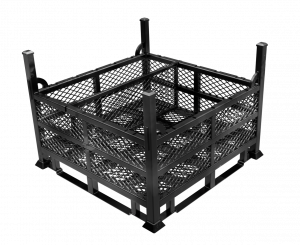

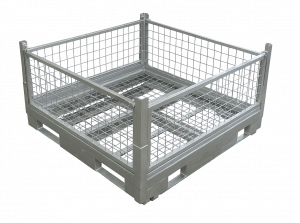

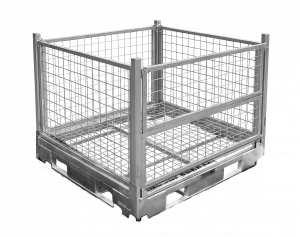

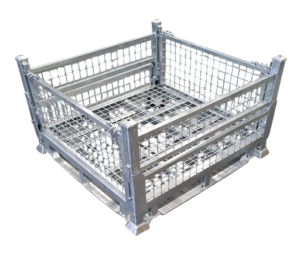

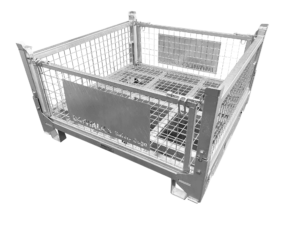

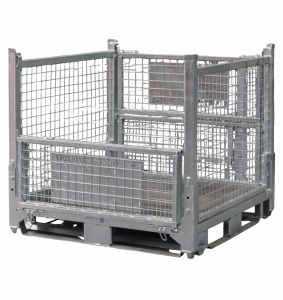

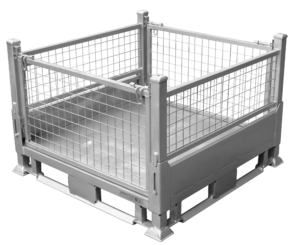

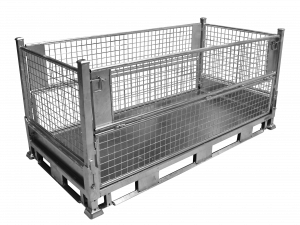

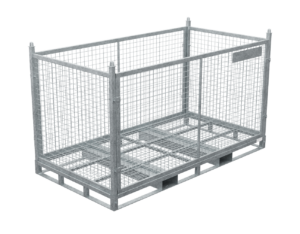

Full steel mesh cages are built for heavy-duty use, giving operators clear visibility and strong protection across storage and transport. Designed for stacking and racking, these cages keep assets secure while allowing airflow and easy identification. Each unit is engineered to handle demanding industrial conditions, from mine sites to warehouses, helping teams stay organised and compliant during every stage of logistics.

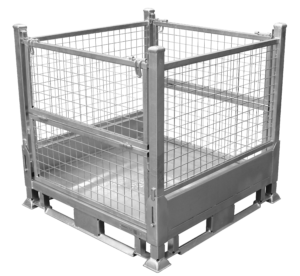

When paired with other DAYWALK systems, such as sheeted cages, they create a flexible storage network that adapts to different load types. These steel mesh storage cages are also compatible with heavy equipment transportation solutions, allowing safe and efficient handling across site operations.

Whether used for long-term yard storage or high-frequency transport, each mesh cage is designed to improve safety, productivity and peace of mind.

Showing all 11 results

DAYWALK’s heavy-duty mesh cages are made from galvanised steel and tested in Australia’s toughest environments. Every weld, hinge and latch is designed for strength, ensuring the cage performs reliably under heavy loads. The open-mesh structure improves airflow, helping reduce corrosion risks and making visual inspection quick and simple.

Built with the same engineering standards that define DAYWALK’s Design Logistics range, these mesh cages are part of a complete system built to protect people and equipment. They integrate seamlessly with pallets, bins and lifting gear for safe movement across sites.

For longer service life, operators can maintain surfaces with rust prevention products or apply a rust preventative coating to safeguard against harsh conditions. Together, these steps help ensure each cage continues to perform as intended — safely, efficiently and with confidence.

DAYWALK cages are engineered well above typical industry standards. Many low-cost alternatives on the market use lighter materials or basic fabrication methods that are not suited to heavy industrial environments. We design every cage for long-term strength, consistent load performance and reliability across mining, resources and freight operations. This higher level of engineering is reflected in the quality, safety and service life our clients rely on, which is why DAYWALK products remain a trusted choice even when compared with cheaper, lower-grade options.

Steel mesh provides strength and visibility. A wire mesh cage design allows air and light to pass through while protecting goods during storage or transport. In industrial environments, mesh panels help prevent damage by securing loads without restricting inspection or ventilation.

Each mesh storage cage is rated for heavy industrial use, with capacities typically ranging from 1 tonne to 1.5 tonnes depending on configuration. Always refer to the load rating plate or technical specifications before lifting or stacking to ensure compliance with site safety standards.

Mesh cages combine visibility, security and ventilation in one design. They make it easy to check contents without opening the cage, improve airflow to prevent condensation and stack neatly to save space. Lockable mesh storage cage options can be added for extra asset protection during storage or transport.

Steel mesh is exceptionally strong, capable of withstanding high tension and impact. When galvanised, it resists rust and deformation even in outdoor or coastal environments. The welded intersections distribute load evenly, providing a secure structure that maintains shape under stress.

Yes. Steel mesh storage cages are built for outdoor use, especially when hot-dip galvanised. They resist corrosion and maintain strength in wet or dusty environments. Regular cleaning and protective coatings can extend service life even further.

Stainless steel mesh cage options are also available for long-term use in marine or chemical environments.