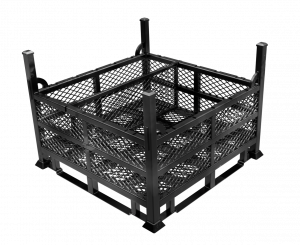

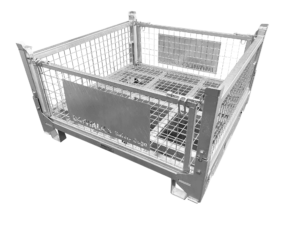

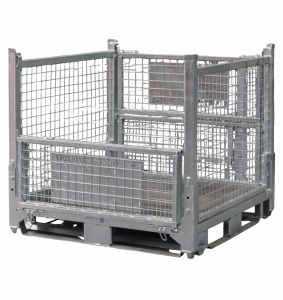

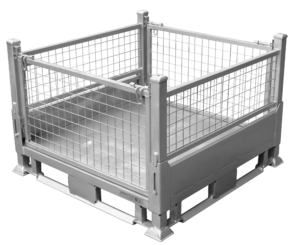

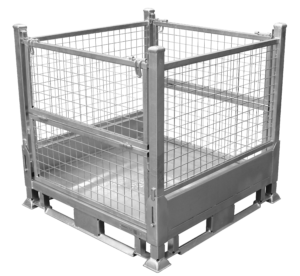

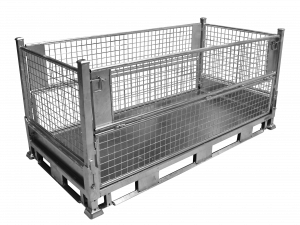

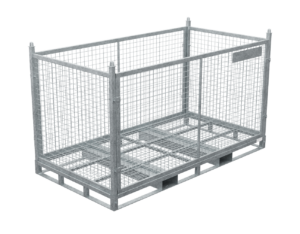

Daywalk’s steel stillages and cages are trusted to perform under the toughest industrial conditions. Every stillage cage is engineered for maximum efficiency and safety, giving teams confidence that stored equipment and components remain protected and easy to transport.

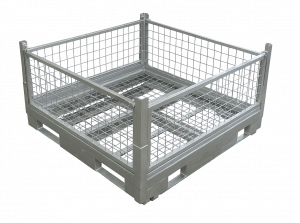

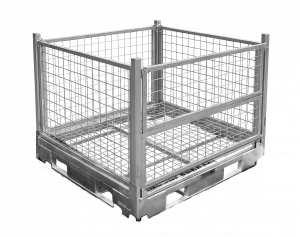

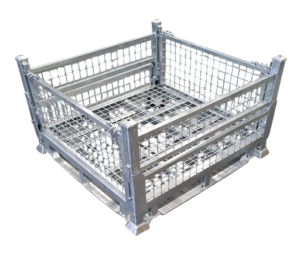

Each design optimises warehouse space and integrates seamlessly with pallet racking systems and pallet cages, improving workflow and reducing handling time. The range includes full steel mesh cages, sheeted cages & boxes and timber based cages, each purpose-built for different storage requirements.

Showing 1–16 of 17 results

Each galvanised steel cage is built for long-term use with minimal maintenance. The hot-dip galvanised coating protects against rust, moisture and wear, proven to perform in wet or coastal conditions.

Daywalk’s heavy-duty sheeted options suit bulk storage and handling. Their powder-coated finish adds extra protection and strength. Along with steel pallets, plastic pallets and bins and timber based cages, these systems form part of Daywalk’s Design Logistics range, working seamlessly to improve safety and productivity.

As a trusted steel cage manufacturer, Daywalk delivers reliable, easy-to-manage solutions — from everyday storage to stainless steel cages for specialised environments.

A steel stillage is a rigid frame or cage used to store and transport heavy or irregular goods. Made from welded steel for stability, it prevents items from shifting during handling and transport. Many designs are stackable and pallet-racking compatible, helping maximise floor space in warehouses and yards.

Stillages are used to organise, separate and protect components in industrial environments. They make handling safer and more efficient by keeping equipment secure and reducing the need for manual lifting. In sectors such as mining, transport and manufacturing, stillages are an essential part of safe logistics.

Heavy-duty steel cages, whether compact or large steel cage systems, are used to contain, secure and protect goods of different sizes during storage or transport. Their mesh or sheeted sides allow for visibility, airflow and safety when lifting or stacking. When paired with VCI Desiccant, they offer continuous protection against moisture and corrosion.

Every steel cage starts with high-grade steel that’s cut, welded and reinforced to meet strict safety standards. Once the structure is complete, it’s hot-dip galvanised, creating a tough zinc coating that resists rust and moisture. This process ensures each cage performs reliably for years, even in harsh outdoor or coastal environments.

Steel stillages and cages are relied on across mining, logistics, transport and manufacturing. They protect critical equipment, streamline storage and reduce handling risks. Built for heavy-duty use and long service life, they’re trusted by professionals who need dependable solutions that withstand demanding industrial conditions.