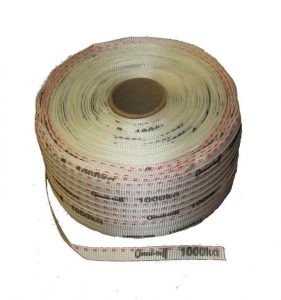

DAYWALK’s polywoven strapping systems help secure, restrain and stabilise heavy items during transport and storage.

A complete poly strapping system typically includes compatible tensioning tools, accessories and straps to bundle and secure loads safely.

Offering both high strength and impressive flexibility, poly strapping kits are ideal for use on loads that have irregular profiles, sharp edges or uneven weight distribution. The straps themselves conform to the shape of the load, reducing movement and minimising damage caused by handling, transit or movement during long-term storage.

Our polywoven strapping systems can be used to secure machinery, fabricated items and industrial assemblies contained within component transport and storage frames. If a load is particularly large or awkward, it can be placed onto a heavy duty steel pallet and secured using appropriate restraint methods. We offer additional safety-focused solutions for these applications, including hold-down bolts, spreader rubber plates, anti-slip mats and adjustable chocks,

Businesses across manufacturing, mining, energy, infrastructure and heavy industries rely on heavy duty poly strapping solutions to assist with packing, freight and internal handling. Our systems can be applied manually or with mechanical assistance, suiting both fixed-site and field-based operations.

Showing all 11 results

Polywoven strapping systems offer various advantages over conventional materials. Their unique combination of high tensile strength, light weight and reusability makes them an easy, cost-effective load restraint solution. They are non-corrosive, meaning they won’t degrade when exposed to moisture.

The systems are also cost-effective. Most straps can be used for multiple applications, while poly strapping machines and tools create a fast, reproducible process for little extra outlay.

At DAYWALK, we ensure every polywoven strapping system offers reliable performance in demanding environments. Our focus on quality and dependability protects your assets, reduces risks during handling and maintains compliance with transport requirements. Discover how our polywoven strapping solutions could fit into your heavy equipment transport system today.

Polywoven strapping is made from woven polypropylene fibres. This construction gives the strap its strength, while maintaining enough flexibility to absorb shocks without snapping. The woven fibres also help the straps conform to the shape of the load’s surface, improving the level of restraint compared to a flat plastic alternative.

Polywoven strapping and PET strapping are designed for different restraint applications. Due to their flexible, woven construction, poly strapping is suited to loads where the strap needs to conform to the load shape and absorb movement.

PET strapping, by contrast, is rigid and is commonly used for loads containing cartonised goods, where consistent tension and friction-based restraint are required. PET systems typically rely on plastic welds for joining, while polywoven systems use buckles, which offer flexibility but reduce joint strength.

Heavy duty poly pallet strapping can be purchased to suit a range of load capacities. Weight limits generally depend on the strap width and weave density, as well as the way it will be applied to the load. Contact DAYWALK for further assistance in choosing the best poly strapping tools for your loads.

Yes. Polywoven straps can be used multiple times, reducing both waste and costs and making these systems a viable option for returnable packaging systems. However, a strap should be replaced if it is damaged, weakened or cut during removal.

Yes, heavy duty poly strapping solutions can be used in outdoor environments. The straps are moisture-resistant and do not corrode, allowing them to be used in long-haul freight environments where loads will be exposed to variable weather conditions. Always ensure straps are applied correctly and inspected before reuse.