CHALLENGE

Non-compliant Transport Frames

The existing transport frame methods were proving ineffective for the customer as they were often non-compliant to road-transport standards under Schedule 7 of the Heavy Vehicle National Law (HVNL). With non-compliance, the frustration of not knowing if the frame is safe, is costly and can be a real challenge. This calls for a solution which can be relied on to safely transport heavy components and be flexible enough to adapt to multiple requirements on-the-go.

SOLUTION

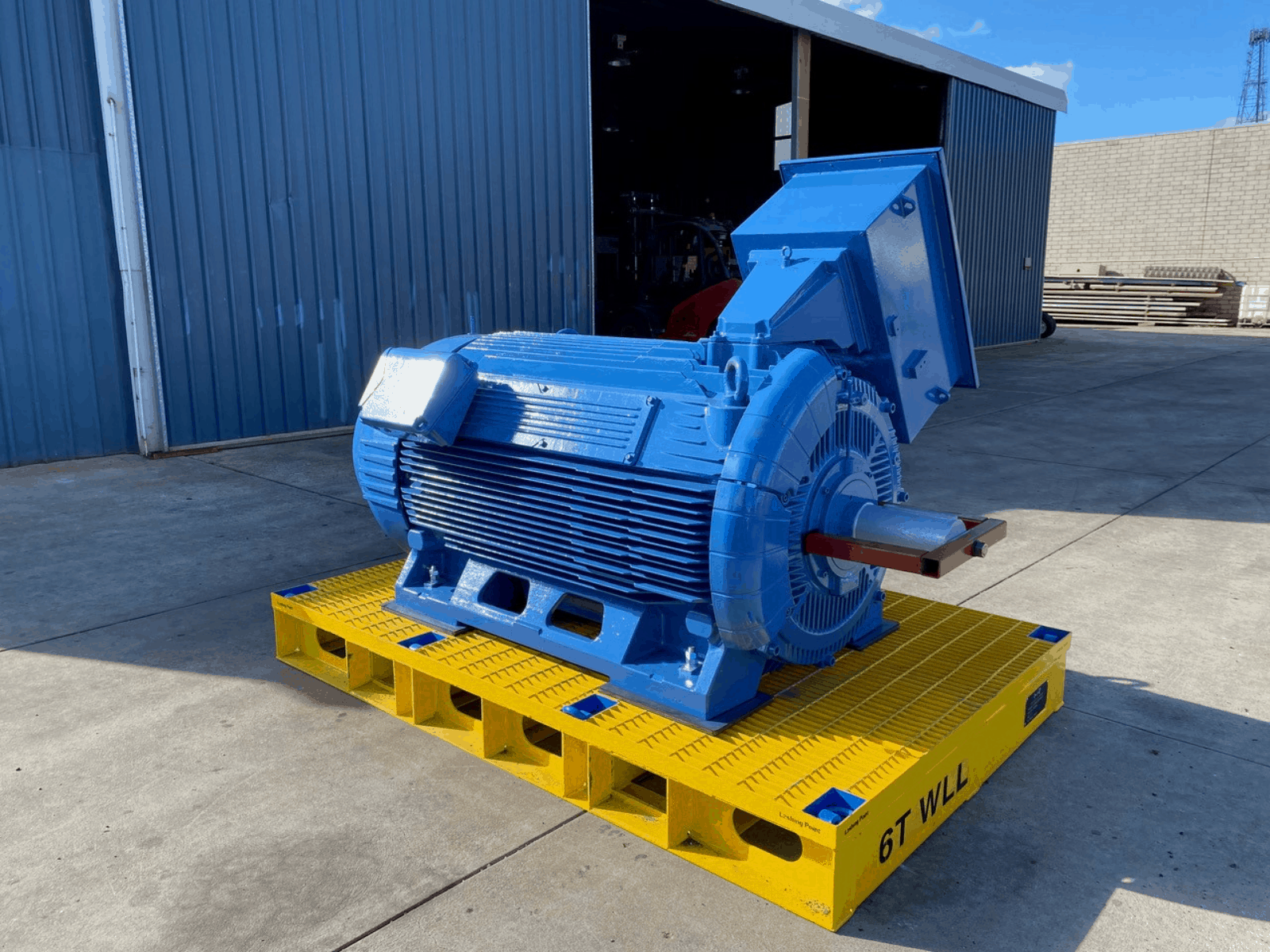

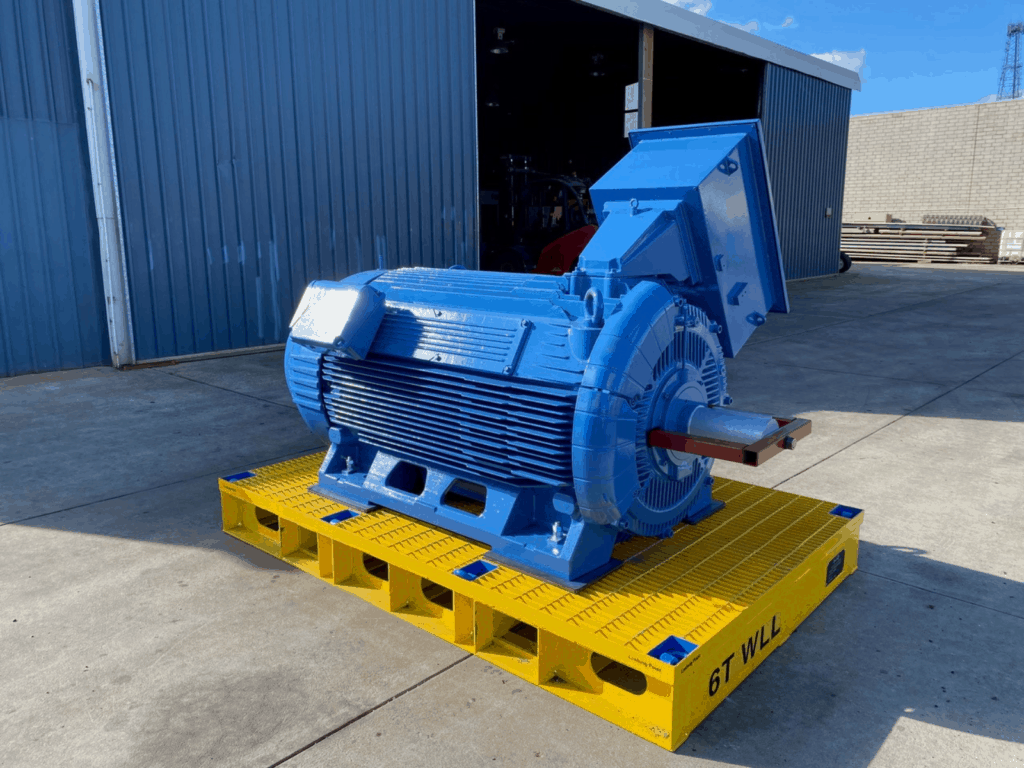

Modular Transport Frames

To meet the customer’s need, DAYWALK was able to deliver our patented modular transport frame system. With this best-in-class system, you can easily swap and change what you are transporting. In the case of this electric motor, it is easy to restrain with the DAYWALK top-load bolts and other modular accessories. Along with safe transport from the modular transport frame, the SKN Coating was coated onto the bare metal shaft to protect for rust and corrosion while in transport. Another great transport outcome.

Patented Bolt-down System

SKN Coating applied for amazing shaft protection

Lashing lugs for use with multiple applications

Certified for logistics, rated for road-transport