That adage comes to mind – oils ‘ain’t’ oils.

Plastics ‘ain’t’ plastics either.

What does this mean? And how does a busy operator know what plastic type or grade to use to protect their expensive equipment?

The DAYWALK team conducted a nine-month trial some years ago, which revealed some very interesting results (nine months would be regarded as short- to medium-term in the world of preservation).

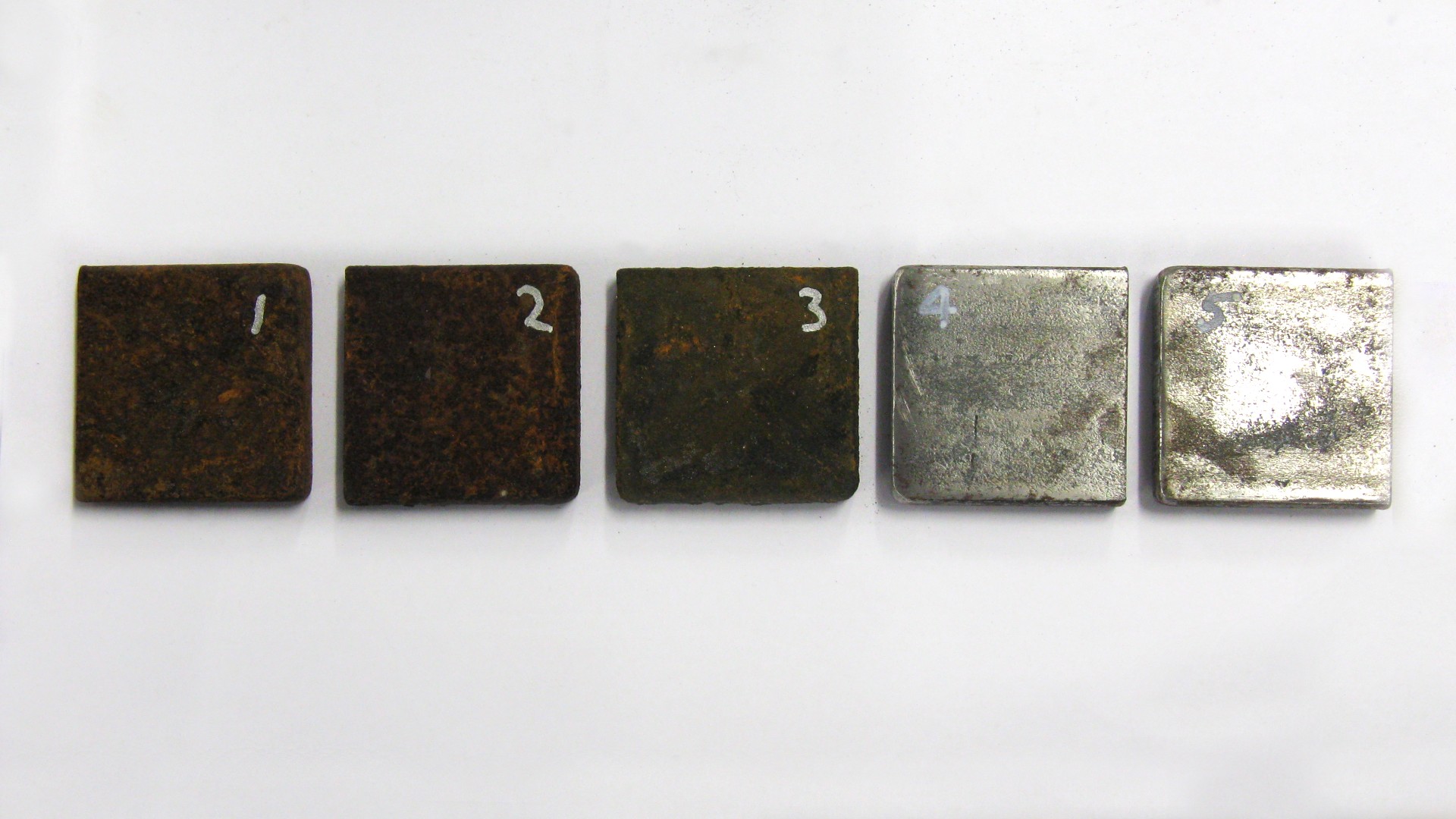

The test comprised 5 pieces of 2” square linished mild steel:

- The first piece was bare metal – with no plastic cover.

- The second piece was placed in a zip-seal bag (standard sandwich bag).

- The third piece was placed in a DAYWALK BRONZE rated plastic bag – UV stabilised material.

- The fourth piece was placed in a DAYWALK SILVER rated plastic bag – UV stabilised and VCI rust inhibitor impregnated material.

- The fifth piece was also placed in DAYWALK SILVER rated heat shrink plastic – UV stabilised and VCI rust inhibitor impregnated material; this time the material was in the form of stretch film.

The five steel pieces were placed outside and left to weather for nine months. So, whatever the weather conditions were, these pieces were subjected to it all – rain, humidity, dust, UV, heat, and cold.

The technical team’s hypothesis as to predicted outcomes was certainly not totally correct. This is what happened:

- The bare metal piece as expected had totally rusted.

- The zip seal bag had disintegrated, as it had no UV stability and again the piece of metal was rusted.

- The third piece which was covered by the UV stabilised bag was the WORST by a long shot! As many would know, plastic does not form an impermeable barrier. Instead, it breathes and therefore air is admitted into the sealed bag, and with the air comes moisture. Once the moisture is trapped inside the bag, the UV-stabilised heat shrink plastic has no means of dealing with this moisture and the result was that the piece of mild steel resembled that of something that had been ‘stewed’ or pressure-cooked. Because of the UV-stabilised properties of the bronze-rating, the plastic was still totally intact. The outcome of the third steel piece was worse than that of number one and number two pieces.

- The fourth piece, which was covered by the UV- and VCI impregnated silver-rated plastic, was still shiny after nine months.

- Likewise, the fifth metal piece that was wrapped in the UV- and VCI impregnated silver-rated stretch film was also still shiny after nine months.

In comparing UV stabilised heat shrink plastic to plastic that contains both UV stabilisation and VCI rust inhibitor technology, it is obvious that VCI is a critical success factor in long term preservation of critical equipment.

Stay tuned to find out exactly how VCI technology works so effectively in not only dealing with the moisture, but in fact harnessing the moisture to good effect.