What is all this about silica gel and carcinogenic and cobalt blue and non-cobalt?

Can someone demystify all this for me?

Well let’s have a go.

First thing to say is that Silica Gel is SiO2 and whether it has blue-to-pink or orange-to-white or orange-to-green indicating properties, the base product is still SiO2, silicon dioxide.

It is the indicator that determines what the start and end colours will be.

Here is a rough guide of three of the well-known indicating silica gels on the market and the typical indicator that is used in each version:

COLOUR RANGE

- Blue to Pink indicating silica gel

- Orange to White indicating silica gel

- Orange to White indicating silica gel

INDICATOR

- Cobalt Chloride

- Phenolphthalein

- Methyl violet

Certain organisations have done testing as to the safety of such products.

One large organisation conducted extensive tests and the final report that was presented gave them peace of mind that it was still OK to use the blue to pink silica gel, in that while the cobalt chloride was present, the parts per million (ppm) was such a low number that they felt it was safe enough to continue using the conventional blue to pink silica gel.

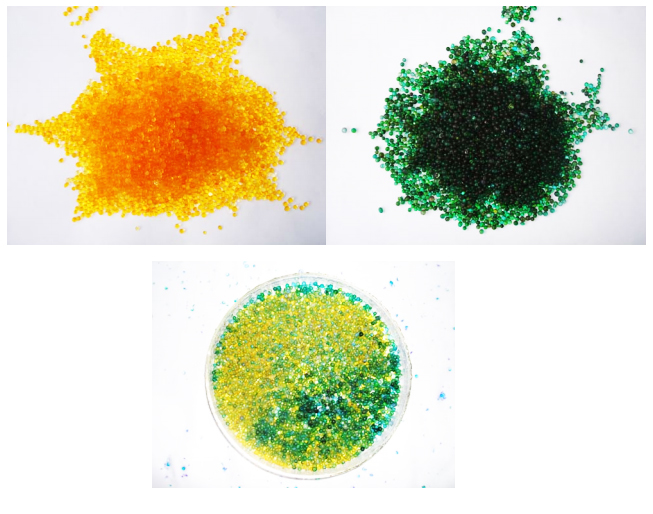

However, since that time that same organisation has migrated to using the non-cobalt based silica gel – and they have started to use the orange to green silica gel, which has the methyl violet as the indicator. The decision would have been somewhat based on the fact that the orange to green silica gel, also known as e-Gel, is more environmentally friendly, and is non-cobalt based, therefore the product is classed as non-carcinogenic.

Some years ago, another large Power company had a difficulty in their supply chain for silica gel so they approached an alternative supplier, who stocked silica gel. The initial response was …Certainly! We can supply you silica gel…it will be the blue to pink style. The customer was absolutely clear that blue to pink was unacceptable to them, and so an alternative was offered: the orange to white silica gel.

About twelve weeks into the trial of the new product a very irate substation maintainer phoned up and complained about the new orange to white gel discolouring after only three months in the field. He was not happy with the style of colour change…from orange to a translucent white and he thought it might have even been affected by the UV rays. Not good!

At that stage, one of the other alternatives were offered and by this stage as you can appreciate, the trust had been somewhat damaged through supplying the previous ‘unacceptable’ product. The orange to green silica gel was offered and this then underwent a scrutinising process and trial, and it performed extremely satisfactorily for the customer.

Since then the e-Gel has become a favourite for electrical departments as it has a strong colour indicating curve, copes well in harsh weather conditions and high-UV areas, and gets the green tick for being non-carcinogenic and more environmentally friendly.

For more information visit Daywalk.com/egel

Click to Download Orange Silica Gel Changing Color PDF

Ready to find out more about e-Gels?

Visit https://staging.daywalk.com/e-gel-silica-gel/ and Drop us a line today for a free quote!