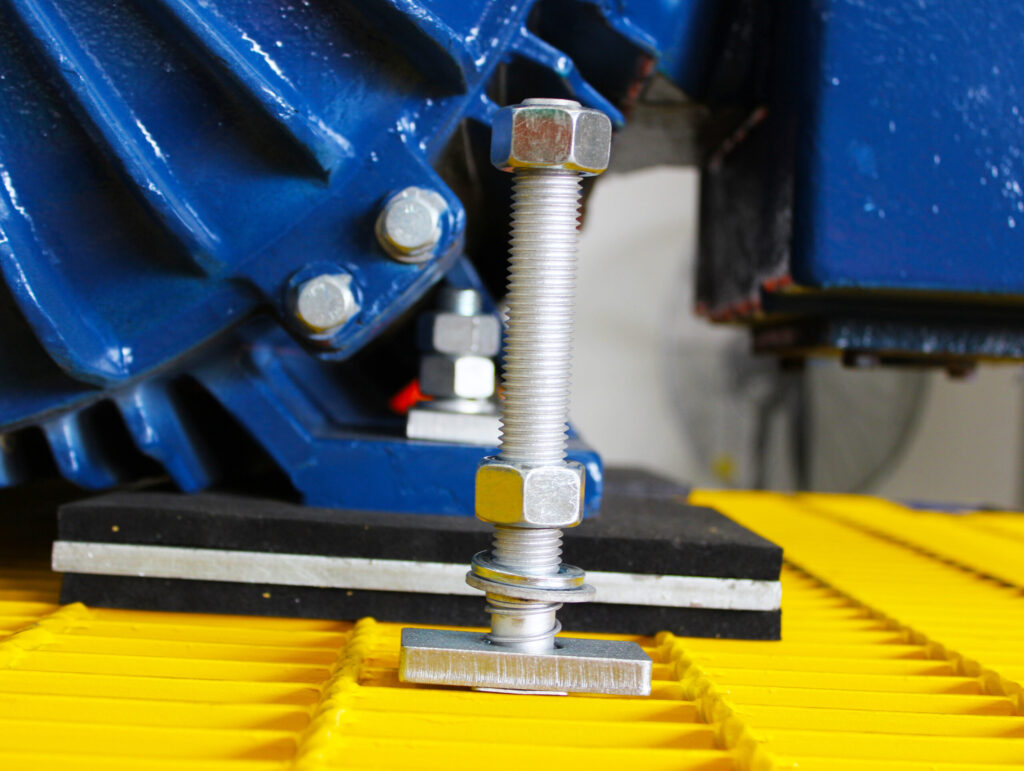

Daywalk’s new Forged Bolt, for compliant and safe transport of heavy equipment and componentry. Compatible with all Daywalk heavy steel pallets these bolts are the toughest on the market. With the risks of transport forces for heavy machinery these bolts are forged not welded.

Australian owned and operated, Daywalk continues to lead the way in storage and transportation solutions. The Forged Bolt is the latest in a range of products that provide the solutions you have been waiting for.

A safe, compliant option, for all your DAYWALK transport requirements. These bolts are forged, not welded, making them the strongest on the market. Fits all Daywlk heavy duty steel pallets.

Forged Bolts Are:

Designed and engineered in Australia

Forged not welded for increased strength

Reduced risk of cargo dislodgement

Daywalk’s Forged Bolts are forged not welded. Welded components cannot compete with continuous steel fabrication in durability and strength. This means safer transport for your driver and for everyone on the road.

Forged Bolts are:

Green-friendly with easily sourced durable steel

Fits all DAYWALK steel pallets

Reusable and recyclable

DAYWALK continues to lead the way with our latest innovation. The Forged Bolt is another testament to our commitment to safety, compliance, sustainability and systemic change that builds a better transport and storage industry for all.

Forged Bolts are:

Australian engineered and designed

Always in stock and available now

Local, world-class fit-for-purpose solutions

Certified Innovation Patent No. 2020101895

290mm

190mm

The Daywalk Forged Bolt is the only product on the market with a fully certified, end-to-end transport pallet & top mounted bolting system. Top mounting prevents the need for personnel putting hands near suspended loads or through the inside of pallets during installation.

Yes. Daywalk’s forged bolts are certified for use with our rated steel pallet system. They are compliant with Australian transport regulations, having been tested and verified to meet the required performance standards for load restraint as determined by the Load Restraint Guide 2018, published by the National Transport Commission.

Daywalk’s forged bolts are capable of safely holding and transporting heavy and high-stress loads such as large machinery, industrial equipment, heavy construction materials and steel components. The capacity of the bolts ranges depending on their size (either 190 mm or 290 mm thread length are available). Our compliance with Australian transport standards further ensures that these bolts are suitable for safely transporting goods that may experience vibrations, impact and shifting forces during transportation.

No, these forged bolts will not break during transport. Thanks to their high-strength alloy composition, precision forging and heat treatment, they are engineered to resist breaking even under heavy pressure. By following our guidelines for installation, load weights and maintenance, you can expect each bolt to last up to 10 years.

Forged bolts are made from high-strength alloys specifically chosen for their exceptional durability and resistance to stress. These alloys typically include carbon steel or alloy steel, providing the strength necessary to withstand heavy loads and harsh conditions.

The coating is made from heavy-duty mechanical galvanised material. This ensures DAYWALK’s forged bolts deliver superior performance, with exceptional durability and weather resistance.

Forged bolts are made by a process of heating the alloy to a malleable state before being shaped under extreme pressure, enhancing their durability and structural integrity. Unlike traditional methods, threads are not cut in. They are added through rolling, which strengthens the material and is then followed by a heat treatment to optimise hardness and resistance to stress. The forging process also aligns the grain structure of the metal, giving it enhanced resistance to wear and impact, making it far better suited for heavy-duty use than its non-forged counterparts. Finally, the bolts are coated for corrosion protection and undergo rigorous quality testing to ensure reliability under harsh conditions and heavy loads.

Overall this construction method is superior because it produces a more dense and resilient metal structure, ideal for high-stress applications. Just like a forged chef’s knife, which is stronger and maintains a sharper edge longer compared to non-forged knives, forged bolts also deliver greater reliability and durability.

Yes, this is a unique system designed and patented by DAYWALK Australia. It combines the superior strength and durability of forged bolts with the robustness of steel pallets to create a reliable and secure load restraint method, especially advantageous for transporting extremely heavy or high-value cargo.

DAYWALK designed the steel pallet and then, through field testing the break point, moved on to bolts because many transporters end up mixing and matching bolts. Forged bolts ensure that loads remain stable without unintentionally creating danger through the use of mismatched and weaker bolts.

This specialised approach ensures that loads remain stable, reducing the risk of damage or accidents during transit and can be tailored to meet your specific industry requirements while maintaining regulatory compliance, such as the Australian Load Restraint Guide and Chain of Responsibility laws.