Test

The company tested the preservation methods on two C175 engine lifting pins.

One was wrapped in a copper film.

One was wrapped in UV-VCI film.

Parameters

- The test was conducted over six weeks.

- Components were exposed to high humidity and rain on outdoor pallet racking.

- An incision was made to both wrappings after four weeks to simulate real-world damage.

RESULTS

After six weeks, the company unwrapped and compared the components.

A sample gear – with no rust protection – experienced severe corrosion over the same period and under the same conditions. The Reactive Copper Technology also didn’t fully prevent corrosion, with marked rust on the pin.

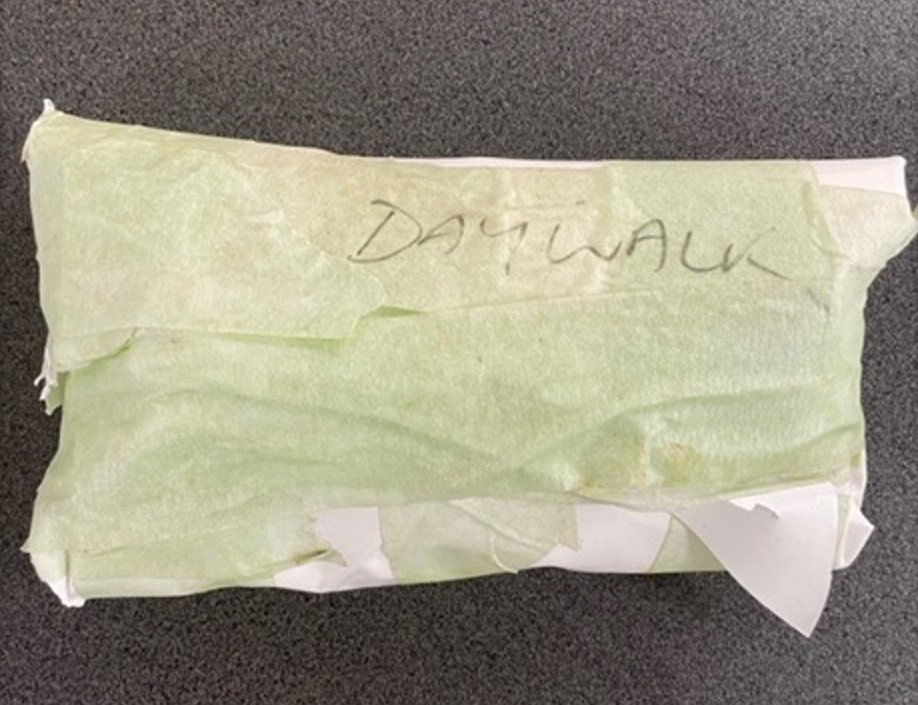

eVCI technology showed superior performance – with zero rust. The vendor noted that it was a “great result for the Daywalk product”.

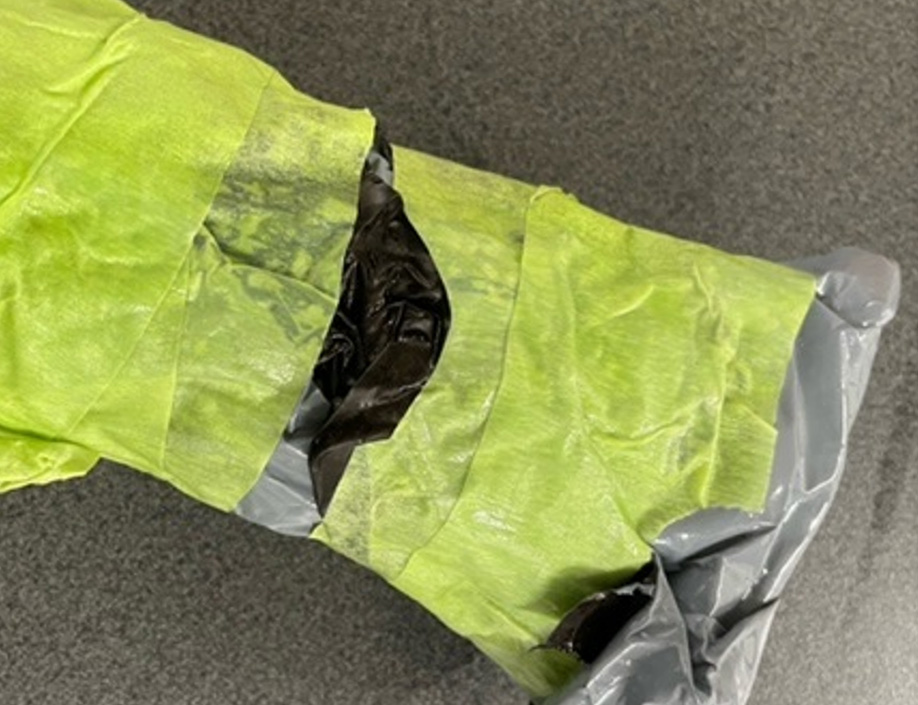

Copper-based solution

Visible corrosion

Daywalk VCI solution

No corrosion

WHY DAYWALK eVCI

Environmentally friendly

Fully recyclable and requires only half the film compared to other anti-corrosion technologies

Economical

Competitively priced and effective with only one layer of film for both UV and rust resistance

Effective

Proven protection in multiple mediums – and in the BHP specification as a suitable preservation method