Almost every consumer product or industrial material has spent time sitting on a pallet. Imagine how long it would take, even with a forklift, to load or unload freight if the pallet wasn’t invented. Wooden or timber pallets remain the most common type used globally, making up more than 90%. However, slowly, the steel pallet is making its way into many industries and companies. This is because steel pallets are proving to be a much safer onsite option than timber pallets.

Are timber options really that unsafe?

Timber pallets will eventually break and splinter as wood will rot with age, or the pallet has been continuously carrying heavy loads at or close to 2 tonnes. At more than this, wood will break easily. Damaged pallets will have protruding nails that can cause injuries. So will wood splinters that are sharp enough.

Another safety concern with wooden pallets is that they can contaminate easily. Spilled chemicals are easily absorbed by wood. Timber can easily harbour bugs, fungus, spores, and other contaminants. This makes wood hard to decontaminate because contaminants will soak deep into wood. This makes timber pallets dangerous to be used for food, beverages, pharmaceuticals, and other consumer products in which contaminants can be easily transferred.

Is timber a risk onsite?

While loading or unloading freight, when a timber pallet breaks, the cargo loaded on the pallet may spill over, damaging the goods that can become crushed, damaged, and dented. Spilled freight may also fall and fatally injure workers below.

Splintered wooden pallets may also cause injury to workers. All this will not only be the cause of damage and injury, but will also add to the cost of the supply chain, insurance claims, as well as causing delivery delays.

Inside ports and warehouses, wooden pallets, especially damaged ones, can be a fire hazard. Since wood quickly catches fire, flames can easily jump from one pallet to another.

Why does steel have the safety edge?

Safety is in its strength

Safety is in its strength

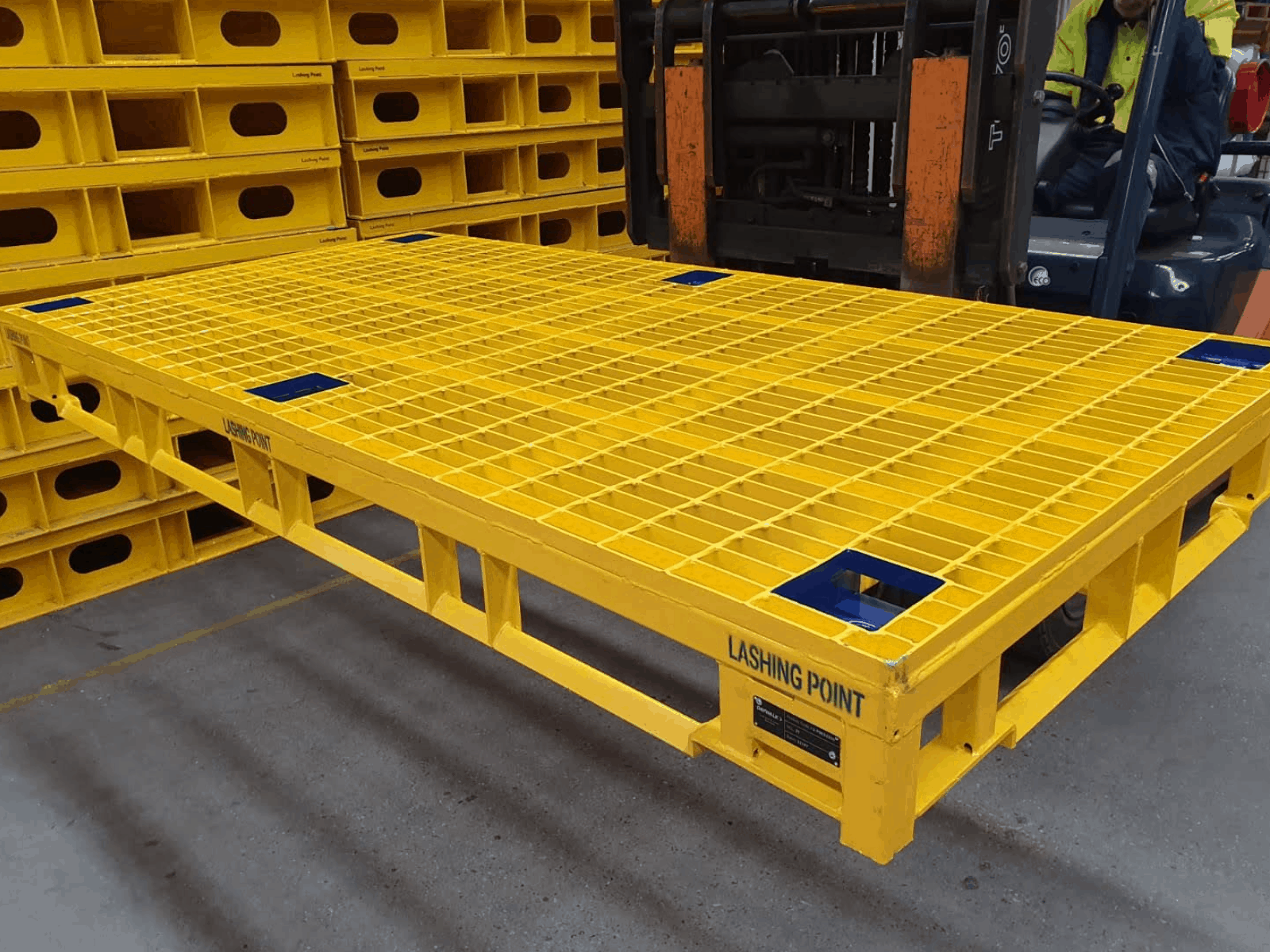

Steel pallets are much stronger than timber pallets. Surprisingly, some Spartan and medium steel pallets weigh less than large timber pallets. This means that steel pallets can take on considerably more weight from freight. This means that goods are less likely to be damaged because they are better protected. The durability of steel also ensures that the pallet will not break or splinter.

Safety in durability

Timber pallets are subject to breaks, splintering, decay, and rotting. In terms of longevity, steel pallets are extremely strong and will last many years longer than the thickest timber pallet. Thus, steel gives a greater value for money because of its longer lifespan.

Safety in hygiene

Steel pallets cannot be contaminated because no insect, fungus, spore, or contaminant can absorb into the metal. Steel can be easily sanitised and cleaned more effectively, quickly removing all infestations, bacteria, and germs on the steel surface. Steel pallets also negate the risk and hazards of fire.

DAYWALK Steel Pallets

DAYWALK features an array of steel pallets from 1 tonne to the 12-tonne range. Types of steel pallets range from Bespoke Solutions, Spartan duty, medium duty, to heavy duty. Steel pallet accessories are also available for the further customised and safe transporting of products, goods, and heavy equipment. For your supply chain needs or new projects, call the Daywalk team today on 1300 662 987, so we can talk about your requirements. For further enquiries, you can also contact us HERE.

Safety is in its strength

Safety is in its strength