Drive Assembly Transport Solution

December 2019

– Custom Solutions

– Load Restraint Engineering

– High-risk Transport Certification

– OEM’s & Engineering

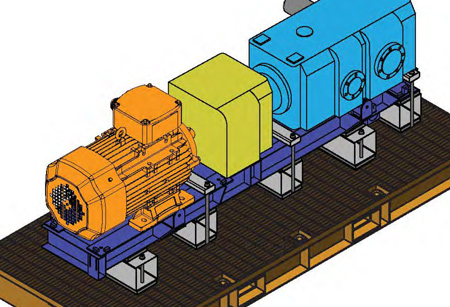

The logistics division of world-renowned industrial-drive equipment manufacturer and distributor David Brown Santasalo, had a complex logistics challenge for drive assemblies. This required a sophisticated, yet universal system that would be able to restrain drive-assemblies with multiple base sizes and complexities.

Additionally, drive-assemblies have a high centre of gravity which adds addition risk to the transportation process. There was also a challenge around the sensitivity of protruding base-mounted components which couldn’t be damaged.

Daywalk collaborated with DBS to develop a universal solution which addressed the applicable transport risks. The assembly of this solution was very simple for the workshop to implement as it used the Daywalk 3500×1500 steel pallet as a universal base. The sensitive base components were protected through using certified dunnage components which are lined with load-restraint rubber.

The challenge of a high centre of gravity was overcome through the development of an adjustable clamping system. The clamping system also served the purpose of a restraint in the absence of mounting plates. In summary, the whole solution was covered with a user-guide which outlined the appropriate solution for an exhaustive range of drive assemblies.

Daywalk presents a joint case study video featuring DB Santasalo’s Codie Ebner & Ben Lewis of FLSmidth. Listen as they give insights on how they are addressing Chain of Responsibility (CoR) in their role >

Speak with our sales team online or by phone and get a quote today.

Brisbane

Perth

Maryborough

Mackay

California

Texas

Sign up for our newsletter to get the latest updates, exclusive offers, and expert insights delivered straight to your inbox.