The challenges of conventional hydraulic cylinder transport

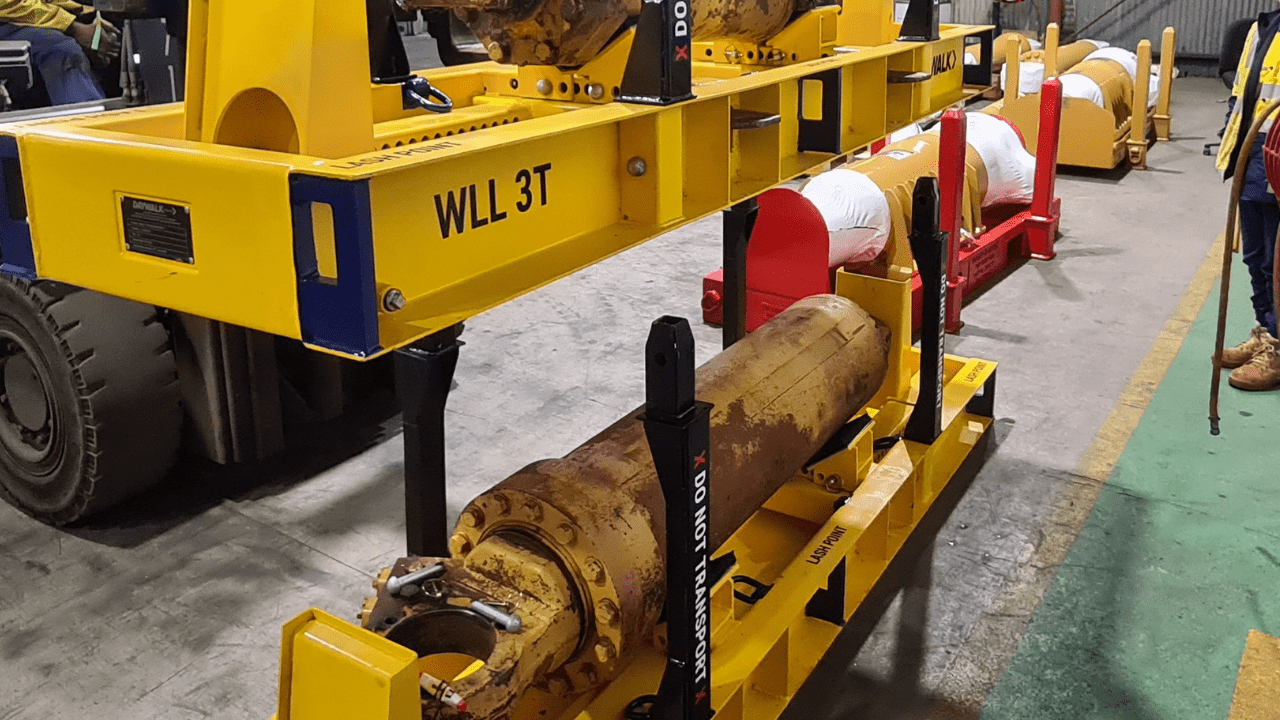

The conventional method of transporting cylindrically shaped heavy industrial equipment is finding a conventional timber pallet or custom steel transport frame that the shaft or cylinder can fit on. The equipment is then tightly strapped using conventional straps or chains. In short, often there are only straps to secure the equipment or the transport frame can only be used for specific sizes of hydraulic cylinder. There are no innovative bolts, holders, or chocks.

Worry no further about non-compliant methods, simply speak to a DAYWALK specialist today.

Another method is to place the shaft or cylinder equipment inside metal cages. The equipment is secured inside the metal cage using straps.

The problem with the conventional methods above is that:

- If two or more cylinders or shafts are being transported, space becomes a premium.

- Not all cylinders and shafts are created equal, leading to customised steel pallets or stillages, adding to the transport cost.

- Using only straps or chains to secure the equipment may not be enough. The chains may come loose and cause an incident.

When transporting heavy and complicated equipment, the DAYWALK line of products has stood out in terms of certified compliance, overall safety, and most of all, engineering innovation. From its basic steel pallets, further innovation brought the different types of steel cages, custom stillages and racks, recycling cages, and steel storage boxes. Recently, DAYWALK’s engineering and innovation team launched the patented cylinder pallet transport frame system.

Now, DAYWALK has launched its latest innovation, the Cylinder Pallet Transport system. This special type of pallet is designed to transport cylindrically shaped complicated equipment such as hydraulic cylinders and shafts. When it comes to specialised component transport, innovation and safety are of all importance in creating compliance for users. The launching of DAYWALK’s new Cylinder Pallet is a perfect expression of the innovation that sets DAYWALK apart.

What is the Cylinder Pallet?

Leading cylinder transport solutions innovatively created for hydraulic cylinder transport, visit Daywalk.com.

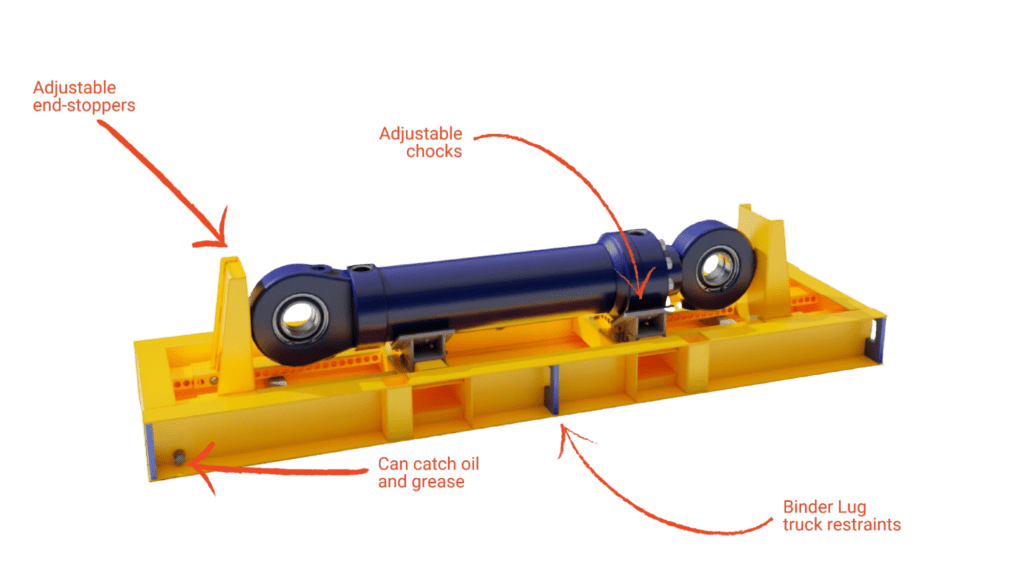

DAYWALK’s Cylinder Pallet is an innovative cylindrical parts logistics solution that is purpose-built for complete flexibility and compliance to carry any type of cylindrical shaft, cylinder, and equipment. The pallet has an independent bi-axial adjustment choke system and adjustable end-stoppers to cater for multiple sizes of cylindrical equipment. The adjustable chocking system means that there is no direct steel-on-steel contact to protect the equipment paint/coating and prevent slipping during transport.

The innovative stacking system means a reduced storage space of up to 50%. The pallet is certified for a capacity of up to 3 tonnes. Other pallet sizes are also available.

Other features include a fitted drip tray and bung for oil capture, forklift compatibility, and arrest lugs for safer truck restraint.

For cylindrical transport needs, get the all-new cylinder steel pallets from Daywalk.

How does the cylinder pallet increase compliance?

DAYWALK’s cylinder pallet completely complies with the Logistics Engineering certification for compliance to the Performance Standards and AS3990:1993. This is defined in Schedule 7 of the Heavy Vehicle (Mass, Dimension and Loading) National Regulation 2018.

But the DAYWALK cylinder pallet goes beyond just minimal safety and regulation compliance. It is a patented industry-first for the transporting and storage of hydraulic cylinders, shafts, and other cylindrical items. It has been engineered to bridge the gap of efficiency and compliance, creating a solution to achieve both while increasing safety levels.

DAYWALK

From its humble beginnings in 1999, DAYWALK has always taken extensive measures to create innovate solutions that limit wastage and extend the lifespan of heavy machinery through protection and increased safety. This can be seen with its products such as the steel pallets, it’s original patented transport frame system, and now, the cylinder pallet. Call us now on 1300 662 987 or visit https://daywalk.com/ for more information, enquiries, or to request a quote.