The existing timber pallet and stretch-film used to transport many small parcels for this large mining company between their logistics centre and mine-site, was proving unsafe and unsustainable for the Supertintendent and his operation. The inconsistency in sizing, the impact on the environment of so much one-use plastic, and the damage done to non stackable pallet consignments, the current system was proving to be a nightmare. The cost of replacement or downtime as well as the anxiety caused to personnel was well worth investing in a reliable smalls management system.

Boxes susceptible to damage

Plastic can only be used once adding to environmental impact

Pallet isn't long-lasting

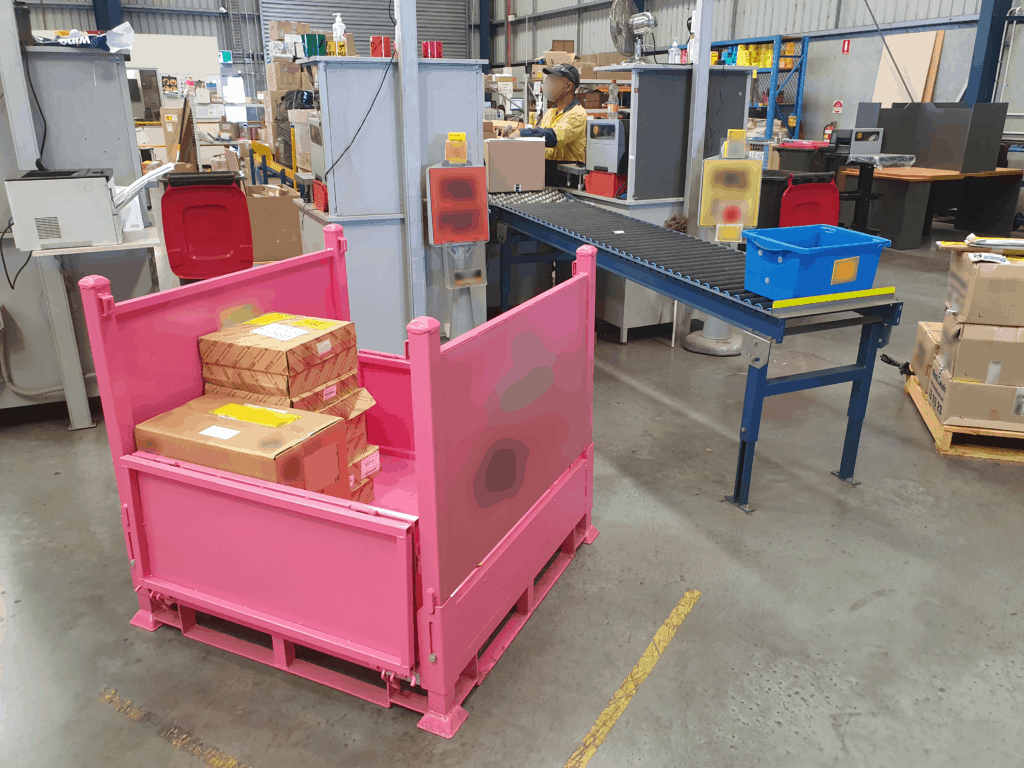

To meet the customer’s need, DAYWALK was able to offer a bright pink fully-sheeted logistics steel stillage/cage that was rated, stackable and racking compatible. The customer’s name was printed on for identification, the steel stillages were painted pink to create awareness around breast cancer, there was barcodes and asset numbers for easy trackability and the client was easily able to fit tracking devices to keep an eye on their steel stillages when they are in service. The functionality of DAYWALK’s sheeted steel cages are fully realised with their greater protection of the shipment in comparison to stretch film and their ability to be collapsed down to a fraction of their original height meaning cost-effective return transport.

Stackable for greater floor-space maximisation

Custom-coated to raise awareness for charity

Printed with company name and with identification plaques

Collapsible for cost effective return transport

Racking and forklift safe