Steel Cage Safety Upgrades

June 2020

– Storage Solutions

– Supply Chain

– Compliance Solution

– Safety Management

– Defence

The Joint Logistics Unit (JLU) contacted Daywalk with a challenge around the use of lead-based paints on their current warehousing cages, which was not only a risk to workers’ health but was also attracting attention of national compliance teams as a high priority to address. The cages were also incompatible with Standard Australian pallet racking, posing a major safety risk of cages falling out of the racking when in storage

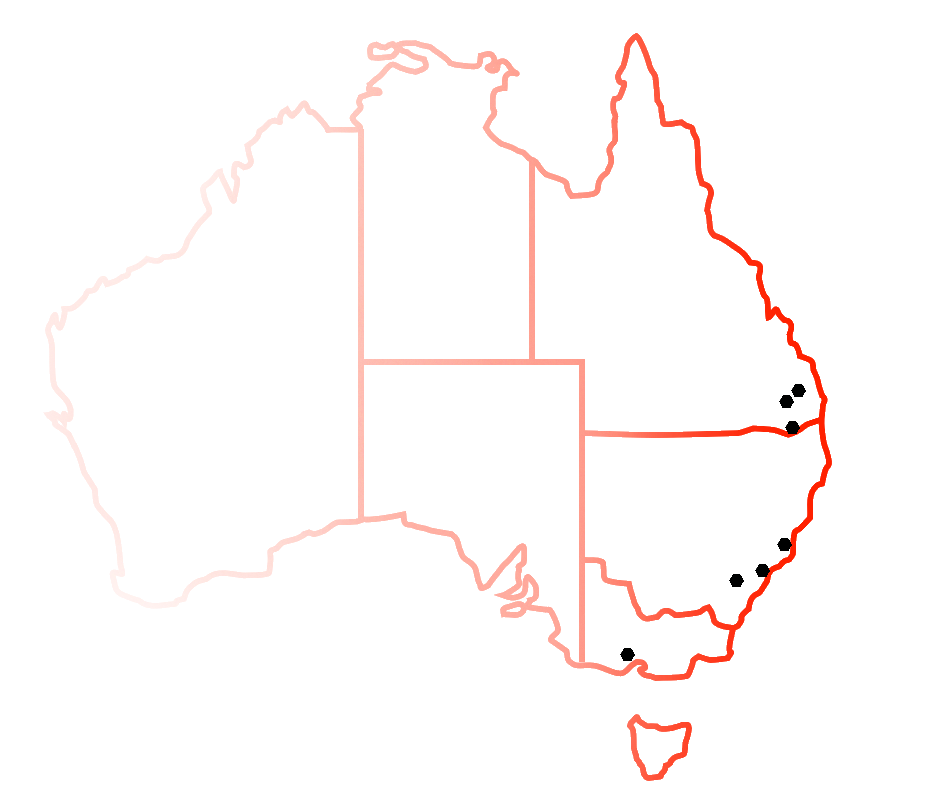

Daywalk was consulted to determine corrective actions that address the issues identified in the customers risk assessment. A safer, racking compatible pallet cage solution was developed with a zinc-plated finish, meeting all compliance standards. The project delivery was coordinated and managed nationally by Daywalk, with cages being delivered on time to customer specifications, to 8 locations across the country. Furthermore, the cages were assembled by disability services in line with Daywalk’s People First ethos, supporting Aussies living with disability.

“The consumables provided all worked well for what we are completing and so far the client is happy.”

ManagerTerminal Services Operator

Speak with our sales team online or by phone and get a quote today.

Brisbane

Perth

Maryborough

Mackay

Sign up for our newsletter to get the latest updates, exclusive offers, and expert insights delivered straight to your inbox.