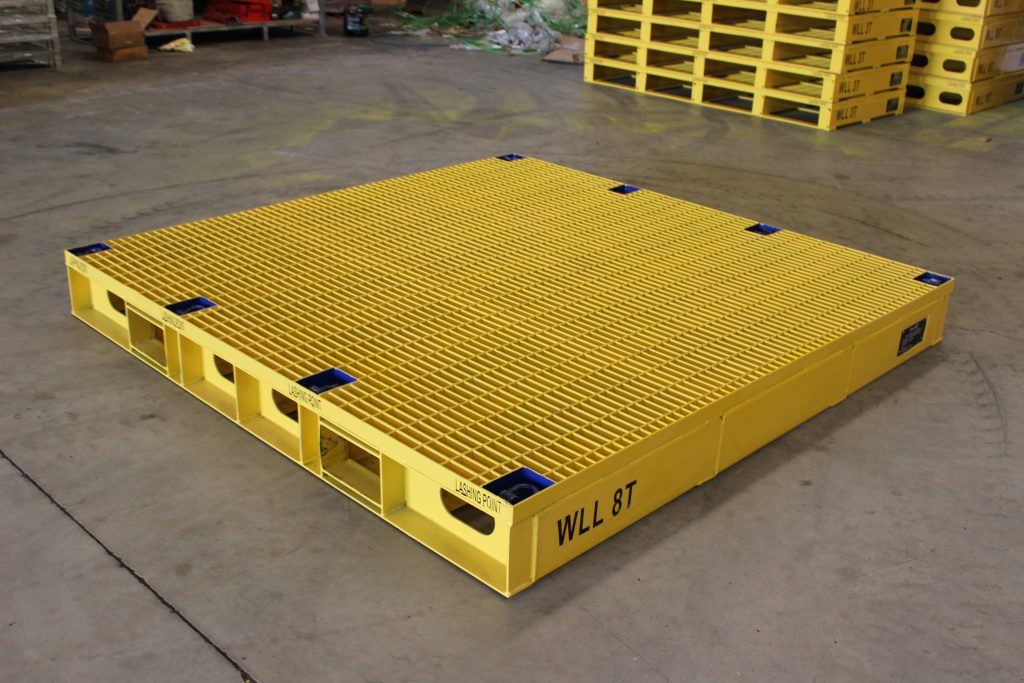

A pre-engineered solution certified for transport, for peace of mind that you will meet your compliance benchmarks.

Larger fort tine pockets ensure compatibility with a wide range of forklift blades, including larger onsite forklifts.

WHY THE 8T and 5.5T PALLETS

Pre Engineered

Off-the-shelf and transport-certified, these pre-engineered solutions offer rapid deployment, ensuring compliance with Chain of Responsibility (CoR) requirements.

Enhanced Compatibility

The redesigned fork tine pockets from tip to heel now accommodate various forklift blade sizes, enhancing operational efficiency and safety.

Durable Construction

Constructed with high-quality materials, they are galvanised and powder-coated for extended longevity, suitable for heavy-duty applications.

RESULT

Optimised Pallet Design Enhances Operational Efficiency

By integrating feedback from Rio Tinto, DAYWALK designed, engineered and certified the new 5.5T and 8T pallets to better suit their equipment. This collaboration resulted in improved safety and performance in component transport operations for all businesses.