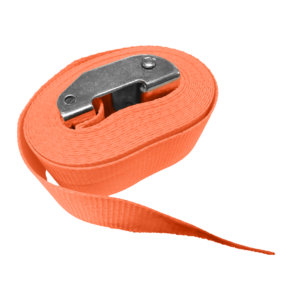

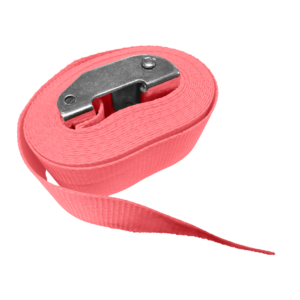

DAYWALK’s Strapping Systems offer efficient solutions for securing heavy loads in tough industrial conditions. The range includes PET Strapping, a safer, cost-effective alternative to steel that is known for its corrosion resistance, excellent tension retention and anti-split properties. Designed for use with manual, battery or pneumatic tools, it ensures ease of use and enhanced safety.

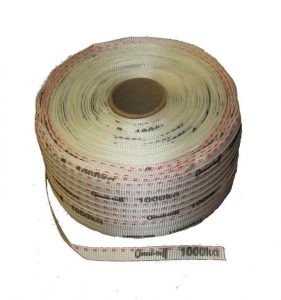

Also in our range is Polywoven Strapping, ideal for heavy or irregularly shaped components. Its interwoven design prevents shearing if cut, and it retains high tension over time. UV- and weather-resistant, waterproof and rustproof, Polywoven straps are built for long-term durability in demanding environments — including use on transport frames and other load-bearing equipment.

With a focus on safety, adaptability and performance, DAYWALK’s pallet strapping systems ensure your goods remain secure and compliant during transport and storage.

Showing 17–27 of 27 results

Pallet Strapping Systems by DAYWALK are engineered to meet the tough demands of industrial transport and storage. Whether you’re securing heavy duty steel pallets, bundling irregular components or stabilising equipment for long-haul transit, our pallet strapping solutions deliver reliable containment across a wide range of applications. Designed for use in rugged environments, our PET and Polywoven strapping options maintain high tension, resist weathering and enhance safety without compromising on efficiency.

What sets DAYWALK apart is our deep understanding of logistics and equipment handling. Our systems are built not only for strength, but also for ease of use. They are compatible with manual, battery or pneumatic tools to streamline your operations. Backed by industry expertise and a reputation for quality, our pallet straps help reduce risk, protect assets and ensure your goods arrive in optimal condition.

Heavy duty pallet strapping is used to secure, stabilise and bundle items during transport or storage, preventing movement, shifting or damage. It’s essential for safely containing heavy equipment, stacked goods or irregular loads — especially on pallets. For steel components or general cargo, strapping ensures your products arrive intact and safe to handle.

Though they are used interchangeably, “banding” properly only applies to securing metal-manufactured systems, while “strapping” covers a wider scope of materials, including PET and polywoven straps. Fully automated, semi-automated and manual hand pallet strapping is more flexible, convenient to handle and suitable for pallet load securing on transport frames or crates without damaging surfaces or edge protection requirements.

To calculate requirements for pallet strapping, measure the circumference of your load (length + width) and multiply by the number of wraps needed, usually two to four, depending on weight and size. Don’t forget to include extra length for tensioning and sealing. For larger loads on Spartan duty steel pallets, factor in additional reinforcement for optimal security.

When strapping for pallets, start by securing the products on a pallet properly and ensure that the weight is evenly distributed. Cover the strap over and below the load, and place it in line with the anchor points of the pallet. Use a manual, battery or pneumatic tool to tighten and seal the strap.

Pallet straps are highly recommended, especially for heavy or irregular loads as they prevent shifting during transit and enhance safety. Whether you’re using Spartan duty steel pallets or lighter options like Xyphos sustainable pallets, proper heavy duty pallet strapping ensures stability, reduces damage risk and keeps shipments compliant with transport regulations.